Our production line integrates three precision stages—sheet extrusion, mesh punching, and biaxial stretching—into a single, continuous flow:

1. Sheet Extrusion

Twin-screw, deep-channel screws melt and homogenize PP/PE into a uniform film.

2. Mesh Punching

Precision die-heads system produces 5 × 5 mm to 50 × 50 mm mesh patterns with quick-change tooling.

3. Biaxial Stretching

Single- and double-direction stretching optimizes tensile strength and dimensional stability.

By integrating these stages in a single, fully automatic computerized line, you get consistent grid geometry, repeatable mechanical properties, and maximum uptime—exactly as Tongjia specifies.

The whole system design software to optimize aerodynamic fluid, symmetric multi-group heat exchange heating fan, adjustable air flow and temperature uniformity, precise temperature control system to ensure product heating temperature uniformity.

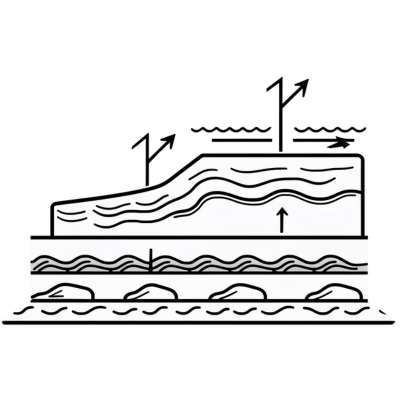

Lay 3D Geonet between foundation and road bottom foundation, used in drainage water between road ground and road bottom ground, can postpone the road life.

In the cold weather condition, lay 3D laminating Geonet can reduce soil frost leave.

The patented technology includes an oil thermostat system with multiple rolls, designed to stretch materials lengthwise in multiple stages for precise shaping and consistency.

Increases pavement load-bearing capacity, minimizes cracking, and prolongs service life.

Enhances subgrade stiffness, guards against erosion, and strengthens retaining structures.

Boosts trackbed rigidity, equalizes ballast loads, and prevents settlement for reliable rail operations.

We offer a 12-month warranty on all mechanical and electrical components, plus optional Annual Maintenance Contracts (AMC) covering spare parts, labour, and priority support.

Yes—Offers custom punch-and-stretch recipes, special mesh patterns, and die-head configurations on request.

Standard wear parts (screws, bearings, punches) are stocked in China and India with > 98 % fill rate for fast turnaround.

If you want to know more information or have any questions,

you can contact us. We will be

happy to help!